IBM Spares in the UK: Why Smart Maintenance Choices Still Matter

30 June 2025 - 4 Minute Read

Brexit brought big changes for many tech businesses but for IBM maintenance customers in the UK, it’s delivered a surprising benefit.

Over the past few years, IBM has invested significantly in local parts holdings. The result? Better availability, faster fixes, and more predictability for clients on a hardware support contract.

At the same time, many third-party maintenance (TPM) providers have moved in the opposite direction, reducing their own inventory and moving to a "just-in-time" spares model driven by cost-saving, not quality.

It’s a quiet shift. But one with important consequences for service, reliability, and compliance, especially for organisations that rely on IBM Power, Storage, or x86 systems in critical environments.

IBM’s Local Stock Investment Pays Off

Since Brexit, IBM has increased its spare parts inventory held within the UK. For IBM Technology Lifecycle Services (TLS) customers, this means faster access to high-quality spares, without the delays or uncertainty of cross-border logistics.

All IBM spares shipped under contract are:

- ETN (Equivalent to New): refurbished and tested to OEM standards

- Secure: fully data-cleansed and packaged to protect integrity

- Up-to-date: shipped with current firmware and revision levels

In short, the IBM model remains engineered for reliability and compliance, especially in regulated sectors like finance, government, and healthcare.

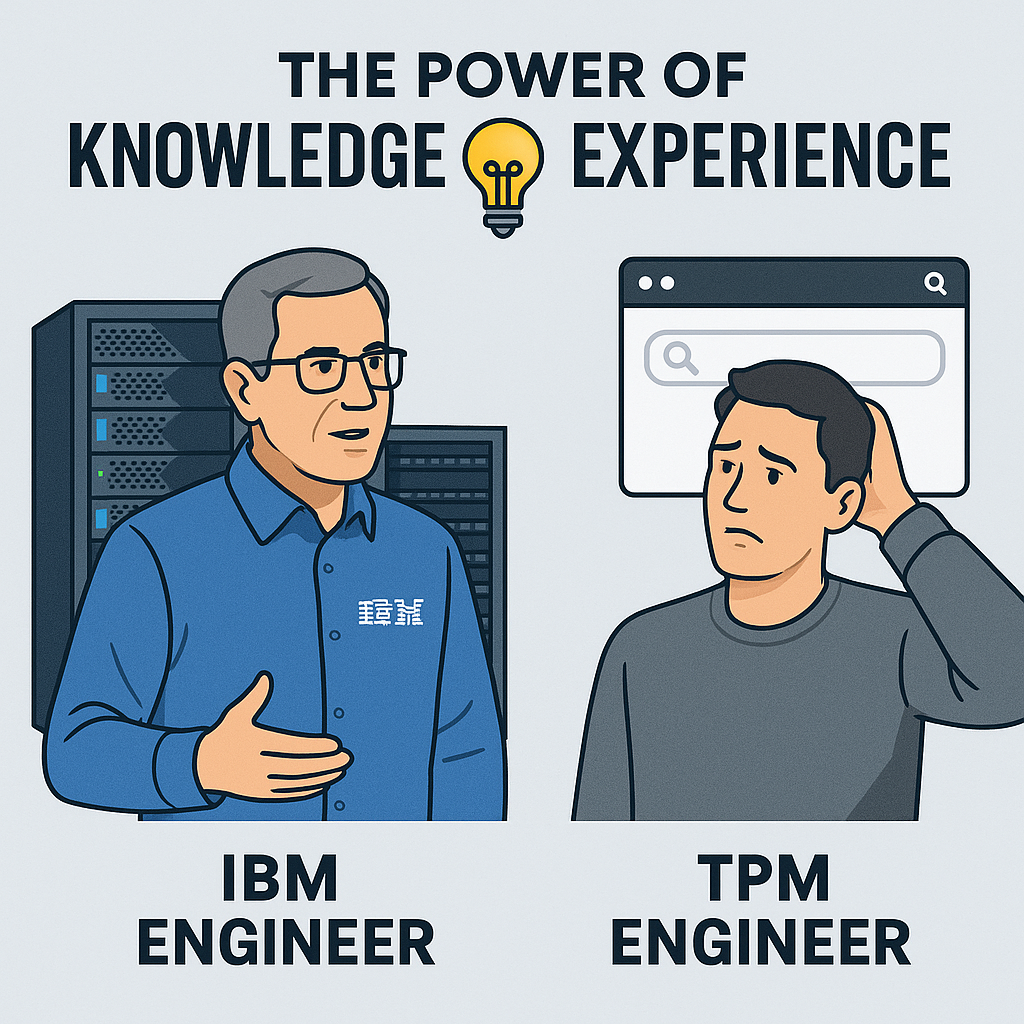

Meanwhile, TPMs Are Chasing Margin

In a drive to boost EBITDA, some TPM providers have quietly scaled back on the very things that once set them apart, like holding stock locally or testing every part.

Not long ago, many IBM TPM specialists would proudly say:

“We have every part for every machine we support, in UK stock and it’s owned by us.”

Today, that standard has all but disappeared from many providers.

Instead, TPMs are increasingly relying on automated, broker-led fulfilment. When a part is needed, their system emails a list of suppliers asking them to quote for direct-to-site delivery, often under SLA, and without any internal handling or testing.

What’s missing from this process?

- Testing and validation

- Data sanitisation

- Consistency of quality or firmware

- Chain of custody

The part may arrive more quickly. But it may never pass through the TPM’s own facilities and you may never know its true history, state, or risk profile.

Fix First or Ship Later? IBM Has the Edge

Another key advantage of IBM TLS is its platform-specific diagnostic tools. These allow IBM to remotely resolve around 50% of faults, sometimes before an engineer is even needed.

In contrast, most TPMs use vendor-agnostic monitoring tools. These can miss deeper issues or take longer to escalate, meaning they’re often dispatching parts or engineers when IBM would already be working on a fix.

Not All TPMs Cut Corners But How Can You Tell?

To be clear: not every TPM operates this way. Some continue to invest in:

- Holding the right IBM spares in strategic UK locations

- Proper part validation and data handling

- Maintaining their own technical testing and SLA oversight

But without transparency or independent verification, it’s hard for customers to know which TPMs still meet that standard and which are just chasing margin.

Making the Right Choice for Your Business

At Baby Blue IT Consulting, we help IBM users understand the real differences between OEM and TPM support models. That includes:

- Benchmarking spares and SLA performance

- Verifying monitoring and escalation procedures

- Reviewing data compliance and security standards

- Helping you mix and match OEM and TPM support to your advantage

Whether you stay with IBM TLS, move to a TPM, or adopt a hybrid model we make sure your decision is based on fact, not spin.

Get in contact on info@babyblueitconsulting.com and 01234 412320

About the Author

Chris Smith

Chris Smith is a sales leader and consultant with over 30 years of experience in IT managed services. With a background in IBM hardware maintenance, he transitioned from field engineer to sales and marketing director, creating the foundations for Blue Chip Cloud, which became the largest IBM Power Cloud globally at the time. Chris played a key role in the 2021 sale of Blue Chip and grew managed services revenue by 50%. He’s passionate about building customer relationships and has implemented Gap Selling by Keenan to drive sales performance. Now, Chris helps managed service providers and third-party maintenance businesses with growth planning and operational improvement.

LinkedIn